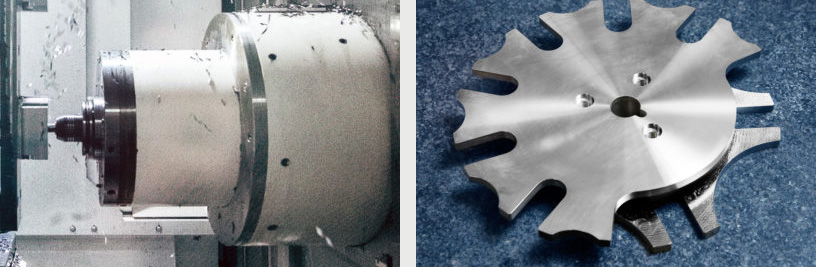

Machine processing

We invest in modern technology and have recently added two FMS systems to meet future demands for quality and efficiency.

Multi-Operation Turning

- CNC-controlled multi-operation turning for workpieces up to Ø 800 mm and 2,000 mm in length.

- Our machinery includes traditional dual-spindle machines and advanced multi-function lathes.

- Vertical turning for large components with a diameter up to 1,950 mm and a height of up to 1,300 mm.

Centerless grinding is available upon request.

Multi-Operation Milling

- Horizontal multi-operation machining for components up to Ø 2,000 mm x 2,000 mm and a maximum weight of 2 tons. The machines are integrated into our FMS systems for optimal efficiency.

- For bed milling, we handle components with a working area of up to 8,500 x 2,500 x 1,200 mm.

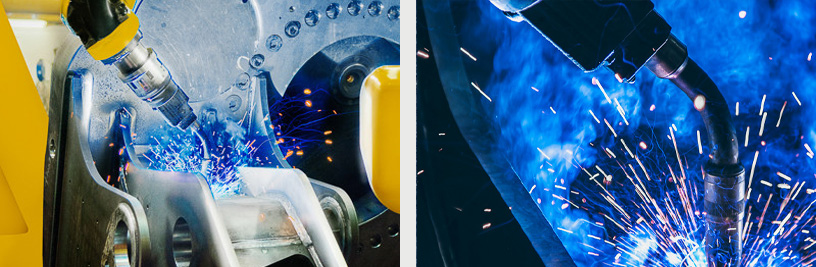

Welding

Welding of heavy plate and aluminum is a key part of our operations. With a certified management system according to ISO 3834-2 and in-house IWS expertise, we ensure the highest quality in every project.

We offer both manual and robotic welding, with the majority of welded products further processed in our multi-operation machines for optimal precision.

Robotic Welding

- We handle products weighing up to 1.6 tons, with or without joint tracking.

- Our latest robotic welding system is equipped with automatic torch changing, optimizing both accessibility and welding positions for increased efficiency.

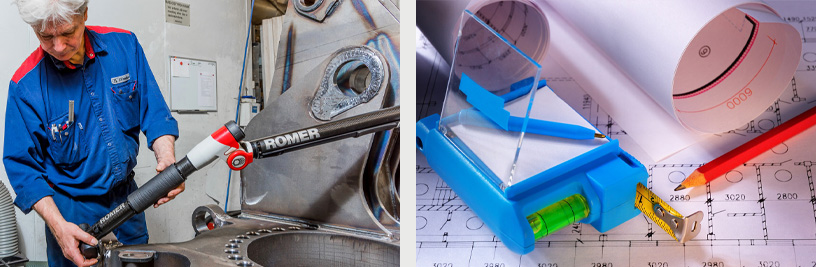

We actively participate in our customers' development work, contributing our expertise in machining and material selection. Through our extensive network of partners and suppliers, we ensure an efficient and flexible process.

We are happy to be involved from the start, whether it concerns prototype production or pre-series manufacturing, supporting your development with modern 3D CAD-CAM solutions for optimal precision and quality.

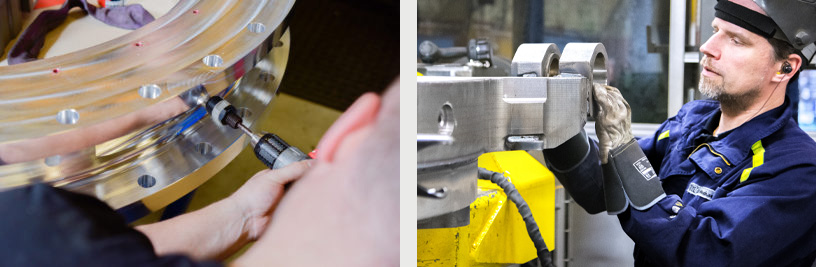

Leak Detecting / Assembly

Our operations include the option for assembly in a clean environment. We can also perform pressure testing and advanced helium leak detection, capable of identifying leaks down to the molecular level.

Machine List

CNC-coordinate measuring machine and Laser Tracker

- 1 Zeiss Contura G2 HTG

- 1 Lasertracker API RADIAN PLUS-50M

- 1 Romer 7525

- 1 Romer 7325

CNC Vertical Lathes

- 1 Toshiba TUD-16

Vertical lathe with 2 pallets.

Working dimensions: Ø = 1,950 mm, H = 1,300 mm.

CNC horizontal lathes

- 1 Doosan Puma 5100LY

Multi-operation lathe with programmable tailstock.

Working dimensions: Ø = 550 mm, L = 2,000 mm.

- 1 Doosan Puma SMX 2600ST (arriving March 2022)

Multi-function lathe for simultaneous 5-axis machining with milling spindle, lower turret, dual spindles, Y-axis, and B-axis.

Working dimensions: Ø = 660 mm (chuck), Ø = 81 mm (bar), L = 1,540 mm.

Served by a Fanuc CR-35iA collaborative robot.

- 1 Doosan Puma MX250

Multi-function lathe with milling spindle, lower turret, dual spindles, Y-axis, B-axis, and bar feeder.

Working dimensions: Ø = 300 mm (chuck), Ø = 76 mm (bar), L = 1,500 mm.

- 1 Doosan Puma 700

3-axis lathe.

Working dimensions: Ø = 800 mm, L = 1,600 mm.

- 1 Mori Seiki SL 250BSMC

2-axis lathe with sub-spindle and bar feeder.

Working dimensions: Ø = 300 mm (chuck), Ø = 73 mm (bar), L = 150 mm.

- 1 Nakamura WT-250

8-axis multi-operation lathe with dual spindles, Y-axis, and bar feeder.

Working dimensions: Ø = 200 mm (chuck), Ø = 65 mm (bar), L = 1,500 mm.

- 1 Takisawa TMM 250

8-axis multi-operation lathe with dual spindles, Y-axis, and bar feeder.

Working dimensions: Ø = 300 mm (chuck), Ø = 76 mm (bar), L = 800 mm.

- 1 Takisawa TMM 200

8-axis multi-operation lathe with dual spindles, Y-axis, and a combination of bar feeder and gantry robot.

Working dimensions: Ø = 150 mm (chuck), Ø = 51 mm (bar), L = 600 mm.

CNC multi-operational Machines

- VARIAXIS C-600, 5 axis vertical multi-operational machine

- 3 Mazak HNC8800-II

- with Flexible Manufacturing System (FMS) for 44 pallets

Working dimensions: 1,400 x 1,200 x 1,325

- 1 Mazak HNC6800-SmoothG

with Flexible Manufacturing System (FMS) for 10 pallets

Working dimensions: 1,050 x 900 x 980

- 1 st Okuma MA-600HB

With 2 pallets and 60 Tools

Working dimensions: 1000x900x1000

- 1 st Toshiba BMC 1000

With 2 pallets and 120 tools

Working dimensions: 2000x1500x1200

CNC bed mill

- 2 st Correa CF 22/20

Arbetsdimensioner 2000x800x800

- 1 st Soraluce SP-10000

med ortagonalhuvud och rundmatningsbord samt kylning genom verktyg

60 verktygsplatser

Arbetsdimensioner: 8500x2500x1200

Robotar

- 1 st ABB IRB 1400

- Welding robot with positioner, maximum capacity: 250 kg.

- 1 st FANUC

Welding robot with positioner, maximum capacity: 3,000 kg.

Additional

- 1 Kent grinder

Working dimensions: 300 × 650

- 1 Lidköping centreless grinder

- Leak detection equipment

- 1 st electronheat Owen

Working dimensions: 2000x2000x4000

- 1 st cuttingmachine Messer multitherm

- Traverses up to 5 ton