Production in own factory with efficient and flexible solutions

Our modern production equipment makes us both efficient and flexible, which gives us the ability to manufacture the entire spectrum from individual prototypes to large series.

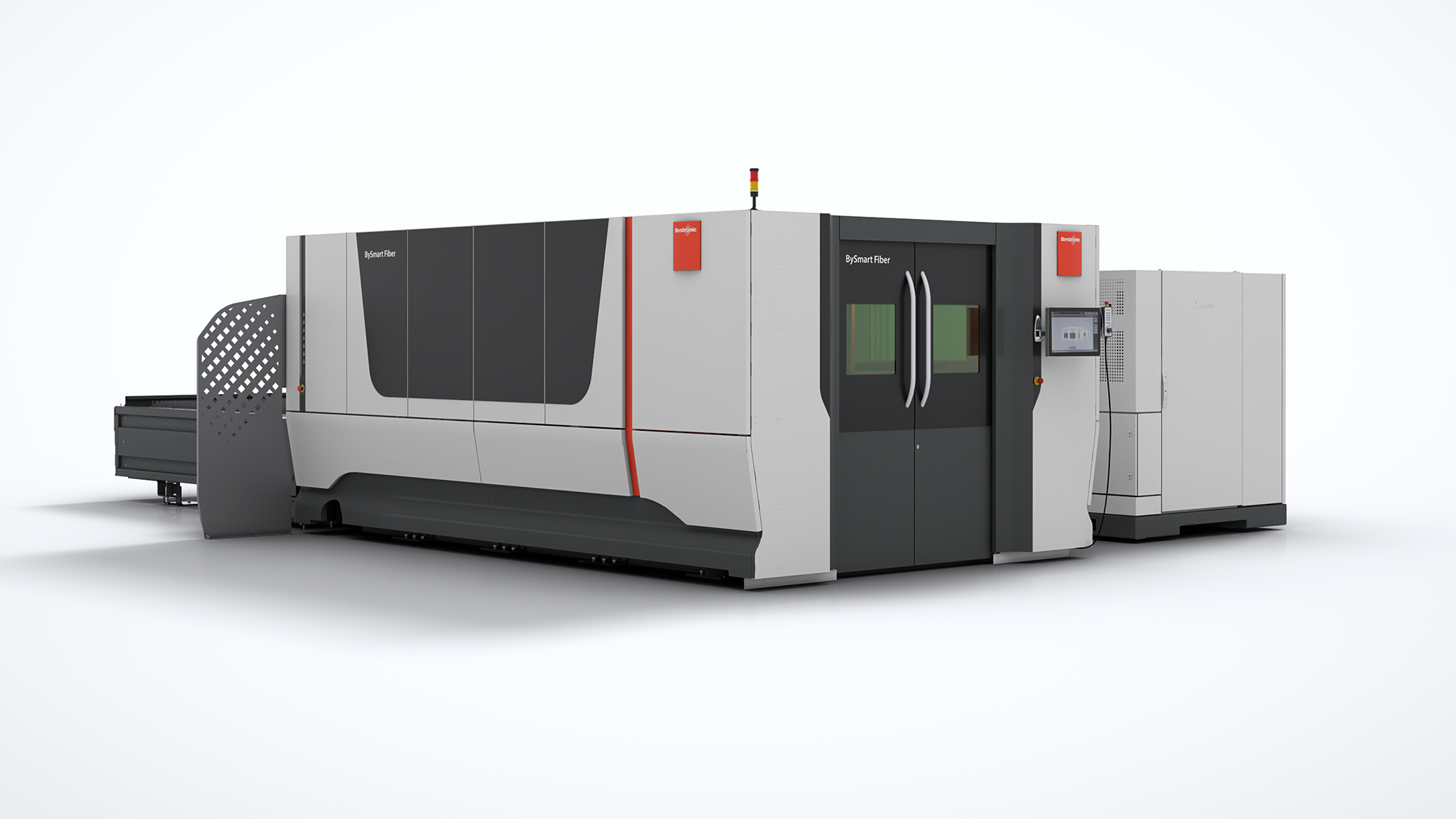

Punching and laser cutting

We have two Prima Power turret punching machines with scissors that are integrated with a pallet handling system (Night Train) in a highly efficient FMS system.

We also have a stand-alone Bystronic laser with associated automatic charging.

The great advantages of using laser cutting are that it is much easier to cut straight, fine lines and complicated contours.

At the same time, it is a technology that can handle rapid adjustments or dimensional changes that make laser cutting a very flexible production.

Edge pressing

We have an automatic Prima Power edge folding machine that is very efficient, especially for larger details that would require 2 operators for manual edge pressing. We also have 4 manual edging presses from the Ursviken brand.

Welding

ISO 3834 – Certified Welding at AQ Enclosure Sollefteå

At AQ Enclosure in Sollefteå, we are proud to be certified according to ISO 3834, an internationally recognized standard for quality assurance in welding. This certification ensures that our welded products are manufactured with the highest level of precision, consistency, and traceability — meeting both industrial and customer requirements across global markets.

What is ISO 3834?

ISO 3834 is a specialized quality standard focused on welding processes. Unlike general quality management systems, ISO 3834 is technically detailed, covering everything from welder qualifications and welding procedures to material traceability, inspection routines, and process control.

In short, it guarantees that every weld we produce is carried out using the right methods, by qualified personnel, and under controlled conditions — ensuring strength, durability, and compliance.

How We Ensure Quality at Every Step

Being ISO 3834 certified means that AQ Enclosure Sollefteå:

- Employs certified welders with valid welding qualifications

- Follows approved Welding Procedure Specifications (WPS) and detailed work instructions

- Maintains full traceability of materials and components used in welded assemblies

- Utilizes calibrated, validated equipment and inspection tools

- Performs systematic inspections and internal quality controls throughout the process

- Continuously trains our staff on current welding standards, technologies, and industry best practices

Why ISO 3834 Matters to You

Welding plays a critical role in the structural integrity and lifespan of any product. By working with an ISO 3834-certified partner, you gain assurance that all welded components are produced according to strict technical and safety requirements — documented, traceable, and verifiable.

Whether we’re manufacturing enclosures, frames, or custom components, you can rely on us for consistent, high-quality welding built on industry-leading standards.

With an IWS-Certified Welder on Site, We Guarantee the Highest Standard and Precision in Welding

We specialize in MIG/MAG/TIG welding, spot welding, and resistance welding in a wide range of materials, including steel, aluminum, and stainless steel.

For prototype production and small series, we rely on manual welding, where our skilled professionals demonstrate their expertise.

We also operate two ABB robotic welding cells, currently welding aluminum products and mild steel using CMT technology. This allows for high production speeds and, most importantly, superior and consistent quality. Additionally, we have the capacity for manufacturing welding fixtures.

.jpg)

Powder coating

Our powder coating line provides flexibility, short lead times, and cost-effective surface treatment. We offer a wide range of colors and textures, ensuring the perfect finish for your products.

Our aluminum enclosures are designed for high corrosion resistance and can withstand harsh environments. They are approved for marine environments and coastal areas with high salt levels (C5M-H), making them ideal for demanding conditions.

Upgraded in 2024 with a new automatic coating booth and powder kitchen for enhanced efficiency and quality.

Whether for small or large projects, you can rely on our powder coating to enhance both the durability and aesthetics of your products.

.jpg)

Mounting

We handle everything from basic sheet metal enclosures to partial assembly of components such as DIN rails, grounding cables, and labeling.

Unlike a traditional sheet metal workshop, we offer our customers a complete solution. This means we often combine sheet metal processing with various types of assembly, providing added value and efficiency.

We work closely with you to ensure our team has the right training and expertise to assemble your products in the most effective way.

Examples of our assembly services include:

✔ Integrated fasteners such as press nuts and press studs

✔ Partial or full assembly of customer products

Our assembly services help reduce workload for our customers, freeing up time and resources for their own production.